Japanese food has been having a huge moment for close to decades now, and the demand for Japanese food internationally also means that diners are much more discerning and sophisticated in navigating the Japanese food and beverage landscape. Many of us have no trouble differentiating between what Hamachi and Maguro is from the sushi menu.

But when it comes to sake, it can sometimes seem obscure and almost incomprehensible (what’s the difference between a ginjo and a daiginjo anyway?) – we sometimes find ourselves struggling to decide on a good sake to order, or a great one to pair with our sushi. We’re here to pull back the veil and break it down for you!

Sake, otherwise also known in Japan as Nihonshu (which translates to “Japan Wine”), is essentially alcohol that’s made from brewing rice and water. The Japanese rice wine usually has an alcohol content that ranges from 13% to 17% and can have a range of flavour profiles that could be characterised from umami to fruity, floral and delicate.

In this part of the Sake 101 series, we look beyond the bottle and get a closer view of how sake is made.

1. Rice Polishing

Before sake rice can begin undergoing the process of fermentation to turn into alcohol, it needs to undergo polishing (also known as milling), whereby a percentage of the outer layer of the rice grain is removed, leaving behind just the good stuff in the centre. The outer layers of an unpolished rice grain contain a large amount of protein and other minerals that taints the flavour of the sake, hence they need to be removed using a high-speed rotating roller (also known as a rice milling machine).

A rice mill used in sake rice polishing (Image Source: www.kem.kyoto)

The desirable part of the rice for sake brewing is the rice grain’s starchy core – the higher the degree of polishing, the higher the content of the desirable core of the rice grain, producing a sake that is smoother and lighter. Sakes are also categorized by the degree of rice polishing – the bottom grade sakes (Futsushu) which do the bare minimum have less than 30% of the outer grain removed, while the highest-grade sakes (Daiginjo) are at least 50% polished. We’ll go into more detail about the different grade levels later.

Anatomy of a sake rice grain (Image Source: tippsysake.com)

Anatomy of a sake rice grain (Image Source: tippsysake.com)

Now you know what you’re paying for when you order that Daiginjo – rice polishing takes hard work!

2. Fermentation

After the sake rice has been polished, washed and steeped in water, then steamed, it’s ready to undergo the fermentation process.

In making sake, koji rice (also known as kome koji) is used as part of the fermentation of sake rice into alcohol. Koji rice is produced by cultivating a fungi called koji-fungi onto the steamed rice.

Koji rice being made (Image Source: www.dewazakura.co.jp)

For those of you who aren’t yet well acquainted with fermentation, the idea of deliberately growing fungi on your rice may perhaps be off-putting. But koji-fungi is actually really good for you – it’s a great source of probiotics which help to improve your gut health and strengthen your body’s nutrient absorption. Oh, the miracle of fermentation!

(Image Source: Japan Sake and Shochu Makers Association)

Before the main fermentation starts, top-grade yeast meant for sake brewing is selected for fermentation and the seed mash is prepared. This seed mash is used as the starter for the fermentation of the main mash.

A ratio of steamed rice and koji rice and water is then placed in the fermentation tanks. The standard ratios are typically 80% steamed rice and 20% koji rice. The fermentation process usually takes approximately 3 to 4 weeks, producing an alcoholic content that can range from 17% to 20%. If a lower temperature is used in fermentation, the process could be longer by about 1 to 2 weeks, and producing sake with a fruitier aroma and cleaner taste.

The fermentation mixture known as moromi is fermented slowly in large tanks (Image Source: dewazakura.co.jp)

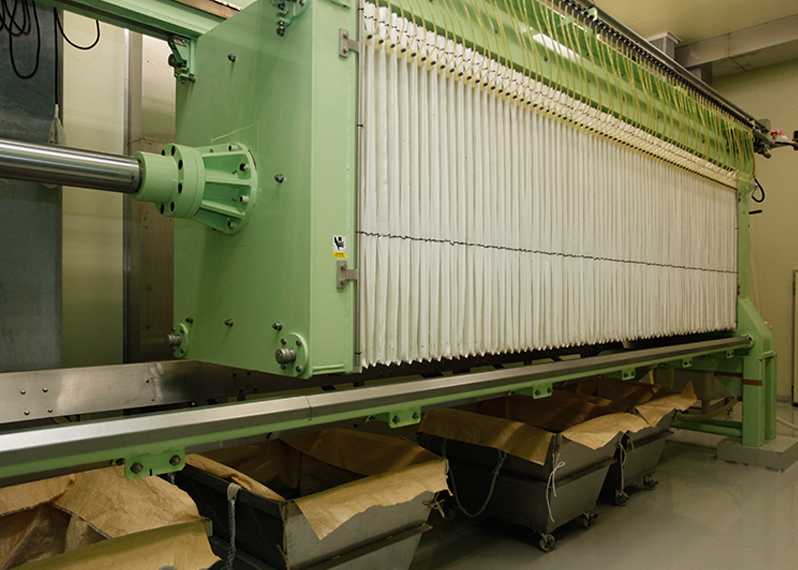

3. Filtration & Pasteurization

Once fermentation is complete, the fermenting mass produced (also known as moromi) is filtered with a cloth, while any remaining undissolved rice and yeast is removed.

Mash filtration machine (Image Source: www.houraisen.co.jp)

After the filtration process, the sake may still appear cloudy with some sediments remaining. The liquid may be left to stand at a low temperature, allowing for precipitation and for the clear sake to be transferred to another tank and filtered to produce a clear liquid.

Most sake undergoes pasteurization, where the liquid is sterilized and the enzymes within the liquid are deactivated. This prevents the actions of the enzymes to continue altering the flavours of the sake further. Sake that is unpasteurized is known as Namazake and tends to be more delicate and unstable than pasteurized sake, tending to have a shorter shelf life.

4. Ageing

For pasteurized sakes, the heating from pasteurization process changes the flavour and leaves the sake tasting unrefined. As such, sake can be aged for 6 months to 1 year.

During the bottling process, sake brewers may add water to the sake to bring the alcoholic content from 17% to 20% after ageing in tanks down to 15%. Nope, they’re not trying to cut corners with this – this is to bring out the more delicate finer flavours in the sake to make them more noticeable to drinkers.

(Image Source: boutiquejapan.com)

So the next time you purchase or order a sake, you can now appreciate the heart and effort that goes into the production process, from polishing, fermentation, filtration, to ageing. The variations in the production process from level of rice polishing to fermentation temperatures also impacts the grade and flavour profile of the sake, so understanding the sake production process is a great springboard into the often elusive world of sakes.

Take a closer look at the different sake grades and classifications with us next!

Kanpai!